LSI-Robway-A Trimble Company now offers both hardwire and wireless system applications that can be load chart programmed on Cranes that may otherwise have no system replacement solutions. With their extensive Crane knowledge and background, they are able to quickly lay out the system with sensors that meet the end user’s needs. Their extensive knowledge of LSI-Robway product line and applications allows Crane Warning Systems to provide the best and most optimal system setup for the customers Crane Indicator Systems needs. A highly loaded project must necessarily be scalable to meet users’ needs. The solution in this area meets the tasks of processing additional traffic, can easily increase storage capacity, perform transactions beyond current capabilities. High load projects developed by Geniusee specialists on average withstand user traffic, exceeding the planned indicators by 2-3 times or more!

Specific data points need to be identified for extraction along with any potential “keys” to integrate across disparate source systems. Even after that work is completed, the business rules for data transformations need to be constructed. This work can usually have dependencies on the data requirements for a given type of data analysis, which will determine the level of summarization that the data needs to have. While ELT has become increasingly more popular with the adoption of cloud databases, it has its own disadvantages for being the newer process, meaning that best practices are still being established. Highly loaded systems face problems with the operation of physical and network nodes all the time. Developers embody the architecture and implementation of the project so that minor failures do not entail problems in the operation of the software solution.

Custom off the Shelf Load Cell

Processing centers and systems must be resistant to failures in the operation and maintenance of hard drives, power supply, etc. Managing the development of high-load projects requires regular load testing at all stages of development. Highload is when traditional approaches to the work of the IT infrastructure are no longer enough. For the system to function stably, you need to clearly understand which database it will work with. The process of designing the architecture of a large application takes into account software components, equipment, technical and legislative restrictions, and implementation deadlines.

Jason Garfoot, Senior Technical Advisor for GFS, will show you how a Side-Load System works and how it can be integrated into your paint shop. An ideal complement to Side-Load Systems, REVO Accelerated Curing Systems can significantly increase paint shop throughput. Integrated seamlessly into the ceiling of the paint booth or prep environment in the Side-Load System, REVO Speed or Rapid units can be easily positioned and moved between bays for increased efficiency. GFS Side-Load Systems are designed to accommodate our premium paint booths and prep stations — including Ultra Paint Booths, Ultra CTOF Booths and Aluminum Repair Stations.

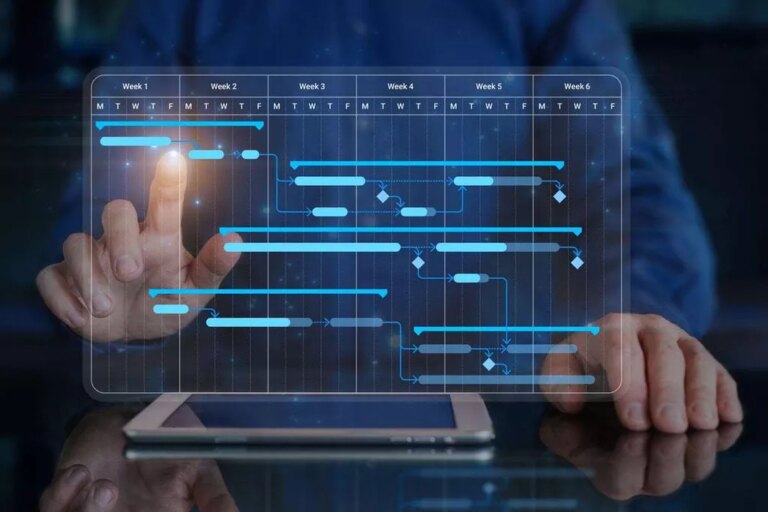

Transforming Project Management with Microsoft 365 Copilot’s AI Technology

RollSeal Doors control contamination and airflow between bays, using a triple-layered fabric and airtight seal to prevent overspray from escaping the booth. Air between layers of the fabric helps maintain desired heat levels inside the booth to meet cure temperature requirements. RollSeal’s fabric doors are impact-resistant; however, if they are punctured or damaged, they can be easily repaired or replaced at a fraction of the cost of a metal roll-up door. With fewer moving parts than traditional roll-up doors, less time and money is spent replacing rollers, tracks, panels and hinges.

As PV power is generated only intermittently between sunrise and sunset, it is possible that generation does not coincide with a grid’s peak power demands. Even if the generation source coincides with peak power demands most of the time, the utility must have generation assets to power the grid in case demand remains high while cloud coverage restricts PV generation. As PV power grows to represent increased contribution to the grid, reliability issues could emerge, similar to the impact of wind power in states where wind has had much greater penetration.

Coding & Development

PNN Soft’s leading specialists have extensive experience working with high-load solutions. We develop sustainable applications that serve a large number of users. In addition, we are developing applications that involve the simultaneous processing of large amounts of data. Our developers of high-load systems implement scalable, reliable, and efficient https://www.globalcloudteam.com/ applications to use. Peak-load shifting is the process of mitigating the effects of large energy load blocks during a period of time by advancing or delaying their effects until the power supply system can readily accept additional load. The traditional intent behind this process is to minimize generation capacity requirements by regulating load flow.

By charging an energy storage system during the off hours of the day and discharging it during the operational hours, the peak demand charge from the utility can be reduced. However, by implementing an energy storage system, it is possible to turn the intermittent source into one with a relatively uniform and consistent output. As such, the large-scale deployment of renewable energy sources coupled with the Smart Grid relies greatly on energy storage systems for maximum effectiveness and optimization.

Microcell Bolt-On Load Cells

With over 20 years experience our scale and load cell application engineers have seen thousands of different applications in every industry. But here’s the problem — there is still no clear definition of the term. In a system with four CPUs, a load average of 3.73 would indicate that there were, on average, 3.73 processes ready to run, and each one could be scheduled into a CPU. In UNIX computing, the system load is a measure of the amount of computational work that a computer system performs. The load average represents the average system load over a period of time.

- When it comes to large data centers, hardware failures (be it power outages, hard drives or RAM fail) are known to happen all the time.

- DigitalMara developed a chatbot that streamlines converting website visitors into customers upon initial contact.

- Initially, the cost of the hardware part of a high load system is considerably higher than the cost of a conventional application.

- Thus far, we have discussed mainly private use or renewable merchant generator peak-load shifting.

- Scott C. Carlson is a staff engineer at Triad Consulting Engineers Inc.

- A Side-Load Finishing System from GFS helped solve problems in his fast-growing body shop.

Mechanical storage usually refers to flywheel, compressed air, or pumped hydro storage systems. The innovative short wave electric infrared technology cures filler and coatings quickly from the inside out, offering the fastest curing time in the industry for both prep and paint processes. Repair cycle time is shortened and rework is significantly reduced thanks to the high-quality, complete cure REVO Systems always deliver. The load point provides users with a uniform, compact and economical solution across a wide range of load cell capacities – from 500 kg (1100 lbs.) through to 30,000 kg (66,000 lbs.). Each load point consists of mounting hardware and an mV/V and mV/V/ohm matched load sensor with true hermetic sealing, C2® Electronic Calibration capabilities, on-board electronic certs, and twenty feet of cable. Each load point assembly is specifically designed to eliminate the effects of unwanted side forces to provide exceptional accuracy and features IP68/IP69K.

LOAD SECURE DRIVER MOBILE APPLICATION

It has received excellent feedback from drivers regarding its simplicity – which is what ensures that they are on tracking so that you can stay connected with your products 24/7, even if they close the app. Floor scales and bench scales are available for industrial weighing requirements. Load cell indicators, amplifiers, and transmitters are available for simple weighing to complex batching operations. This means that this system (CPU, disk, memory, etc.) could have handled all of the work scheduled for the last minute if it were 1.73 times as fast. Why pay money for additional functionality that is not required for work and does not make a profit?

At this rate, only 5% of those who potentially will leave the shop with purchases have a chance to be served well, and even that number can only be reached in the best case scenario. The same holds true for the site – if it does not cope with such a number of requests, рit’s time to change something. If we draw an analogy with an ordinary clothing store, then instead of load systems servers, programming languages and IT stuff like that, there is a simple and understandable consultant, cash register and goods. On a typical day, a consultant approaches each client, helps to choose the size, advises accessories, then escorts to the checkout and calculates the buyer. Crane load indication can be achieved through Load Cells, Lineriders and Load Pins.

The Weighing Equipment Specialists

We will point out the critical points and give recommendations on what really needs to be done and what is better to avoid. Along with developing a strategy, we will offer not only the optimal technical solutions but also economic ones. Cranesmart strives to meet any crane safety challenge put forth by their customers, including large, unique non-crane applications.